Great Wall can produce rotary kiln with diameter Φ1-Φ5m, which is widely used in metallurgy, steel, chemical, refractory, ceramsite, papermaking industries The kiln supporting has rolling and sliding type and the drive can use DC or AC variable frequency control It has various seal types for different working condition Great Wall can also design and customize non-standard rotary kiln according to customer’s special requirements

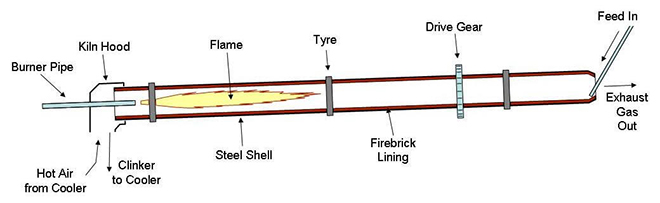

Structure of rotary kiln

Rotary kiln is composed of shell, drive device, support and thrust roller, kiln lining, kiln inlet sealing, head hood and burning device etc.

Shell is the heated rotation part, which is welded by high quality carbon steel plate. It is mounted on supporting device through tyre. Mechanical or hydraulic thrust roller is equipped on supporting device. So it will control shell slide in axial direction. Driving device makes shell rotate through gear according to required revolving rate. Big size kiln has auxiliary drive to make shell rotate at low speed for kiln installation and maintenance request. In order to prevent cooling air into kiln and dust come out kiln, there is sealing device at kiln inlet and output end.

Working principle

Material will be feed into kiln tail through chute in gas chamber. As kiln shell is inclined and it rotates slightly, material will move along round shell and will also move along shaft direction from kiln tail to kiln head. Material will be processed through pre-heat, decompose, calcined and will be feed into cooler. Fuel will be given through gas or coal burner at kiln head and will be combusted in kiln. Heat will be transferred to material by fire radiate, hot air flow, kiln brick transfer. The heat will heat and calcine material enough and make it final product.

Application

Rotary Kiln is a kind of thermal equipment calcines lump, bulk and slurry materials. It is widely used in cement & construction, non-ferrous metals, lime, ferrous metals, refractory materials, industrial chemicals, paper making industries etc.

Features & Advantages

1. Supporting Device: it adopts advanced main shaft structure, automatic temperature measuring device and electrical heating device. And it has optional flow support.

2. Thrust roller: It has mechanical type and hydraulic type. The hydraulic thrust roller is equipped with advanced hydraulic controlling system.

3. Drive device: It has single drive or double drive. The adjustable-speed motor, DC motor or frequency variable motor control kiln rotation speed. And has features of reliable running and high efficiency.

4. Tyre shim: The shim under tyre has fixed type and adjustable type. The adjustable shim has features of simple structure, easy replacement and maintenance without any damage to shell.

5. Sealing device: Various types of sealing device are available for different kiln, such as cylinder tighten sealing, spring tighten sealing, graphite block sealing, spring graphite, fish scale type seal etc, which has good sealing effect.

6. Kiln head hood: It has fixed type and flexible type.